|

|

Posted 9/23/2005 8:46:04 PM Posted 9/23/2005 8:46:04 PM |

|

|

Forum Member

Last Login: 12/9/2018 8:47:32 AM

Posts: 432,

Visits: 2,210

|

|

Moldmaking is an art. It requires experience, and a gift for it. I have seen all kinds of molds made by all kinds of people, in all kinds of different ways with all kinds of different materials. At the end of the day it's about your gifts for being able to reason things out, your experiences, and understanding of how the materials you use function under various circumstances.

I always hesitate to give people cook-book formulas. There are zillions of cook-book formulas in videos. Gotta remember that a video while it may actually help some, is a means of self-promotion. Being a great moldmaker is like learning ti-chi. Every mold must be made to correspond to the current situation. If I cast a car, and Kevin here casts a car, I can guarentee that each of our molds will be RADICALLY different, because both of us has a different set of experiences with different materials, and sees the answer to every problem differently. It's like baking a cake, or being a chef.

My recent thing is weight. I'm on a quest to keep my auto molds so light that one person could pick up a mold the size of an 89 car(all pieces clamped together). But that's just me. You won't find any of my methods in any of the videos or books I have ever heard of. I tend not to follow pre-scribed methods because I believe that they might teach me not to THINK, but to follow without thinking.

|

|

|

|

Posted 9/23/2005 8:59:37 PM Posted 9/23/2005 8:59:37 PM |

|

|

Resident CLTC

Last Login: 4/23/2024 5:59:38 PM

Posts: 2,343,

Visits: 8,997

|

|

| Well said Youngbat, practice patience and perseverance is everything. You can only learn so much reading a book, working with someone who is a master can shave years off your learning curve. Making a mold or just working with fiberglass is an art into it-self.

|

|

|

|

Posted 9/24/2005 11:57:31 AM Posted 9/24/2005 11:57:31 AM |

|

|

Forum Member

Last Login: 3/27/2010 4:47:19 AM

Posts: 471,

Visits: 435

|

|

"If I cast a car, and Kevin here casts a car, I can guarentee that each of our molds will be RADICALLY different,"

Which is exactly how WB looks at it when they try to trace a car back to its origins.

No way in hell is a custom built going to fit back into an original mold. All you need is one small piece to fit over a section of the car.

"If the glove doesn't fit..."

When I was learning to glass, the old-timers used to say "You use the right amount of hardener" but never explained to me what that is.

The reason for that is quite simple. It's different for everyone. I've worked along side glassers that were trained by the same guys as me and we all use different amounts of hardener because we all glass differently.

We use the amount that's right for each of us.

It's something you learn.

My advice is to go pull a mold off a hood you get from the junkyard, then move to a fender and teach yourself. No one's glassing skills are wrong or right, as long as it gets the job done, leaves the original intact and makes a quality part.

One small tip;

"Overwax and you get a wavy part... Underwax and your part and your mold are ruined!"

Good luck!

"Where does he get those wonderful toys?"

He MAKES them you idiot!

www.tunergirlz.com

www.codeoneauto.com

|

|

|

|

Posted 9/24/2005 2:01:42 PM Posted 9/24/2005 2:01:42 PM |

|

|

Forum Member

Last Login: 12/9/2018 8:47:32 AM

Posts: 432,

Visits: 2,210

|

|

It may help to have goals, or expectations from the mold.

Some goals I have set for myself when mold making:

1.clamping edges are smooth and clean, Keys are nice and sharp. all in all like a finished piece into itself. No drilled holes, but geometric keys.

2. If it's clay I'm casting the clay must blocked, basically as good as a finished car. scratch free (go see the thread on gotta have a costume...)

3. contortional stiffiness. When you clamp all the mold sections together, from one end to the other do you get any flexing, or twisting? you want none.

4. This goes hand in hand with 3. I want my mold as light as possible, and be able to retain the contortional stiffiness. topics of discussion: Overstrutting, when and where to strut, or not.

5. air entrapment, or bridging. NOT GOOD.

6. Mold pieces must be self-sufficient. i.e. self postitioning, self standing, i.e. I don't wanna have to mess with proping this thing up in order to use it. i.e. leggs, handles. I don't want to have to bend over, or be in an uncomfortable postion esp. if it's a hand laid job.

7. Parts must be able to release from the mold easily, almost fall off. This has to do with mechanical locks, as well as chemical locks. Be able to spot a potential mechanical lock, and split it up when ness. Must be able to think ahead, and visualize how much of a pain will it be to cast when you get the mold done, when you are in the heat of battle laying it up. Of course you want to minimize that pain.i.e uncomfortable position. too tight of a corner, or cavity. Sharp corners are potential bridgers.

8. substrating various mold releases onto the finished piece: i.e waxing the inside of the mold improperly, and you could have the wax substrate onto the finished piece, then you gotta get that crap off.. echh. So there are alternatives to this in the first place. barrier coats that do not have any bonding cap. with your materials at all. i.e. no wax touches the finished piece.

9. The idea is to make your mold the solution, not the problem. Identify all potential pain-in-the-but situations. Also remember once you start a part of a mold, you must stay on it until you finish it.

10. and this is most important: camoflage you mold so that it looks like someone else's. This may require some paint, phony struts, You can plaster of paris, latex house paint, old chunks of wood. last nights supper. etc.. or better yet have a phony mold set up to look like someone else's in easy access, and the real one off site. no just kidding, I'd recommend doing your own sculpting, and don't sell copies if it's some car that visually belongs to someone else. And don't drive it in busy public places etc.. If you do your own your work(sculpting), long term you'll be more proud, and learn more. Enjoy the process of doing, not just having.

|

|

|

|

Posted 9/24/2005 2:10:07 PM Posted 9/24/2005 2:10:07 PM |

|

|

Forum Member

Last Login: 12/9/2018 8:47:32 AM

Posts: 432,

Visits: 2,210

|

|

| Also I forgot to add that you have to visualize all the functionality that a finished part might need to have. i.e. will you be needing something to attatch at windshield from the inside? If so, better to get this done during the lay-up. It may require some extra work, but the trade off, will be that you get good solid cosmetically pleasing attachments right from the get-go. example: riviting a piece of plastic to your canopy from the outside(echh). Remember that once a part is cured, adding more resin to it will not give a chemical bond. you will have to rely on a mechanical bond. You want both. Go check out the windshield on our 95' car. see how tight the lines are. You can run your fingernail from the top of the canopy and down into the windshield, and not feel the change from the canopy to the windshield.

|

|

|

|

Posted 9/25/2005 11:48:15 AM Posted 9/25/2005 11:48:15 AM |

|

|

Forum Member

Last Login: 12/9/2018 8:47:32 AM

Posts: 432,

Visits: 2,210

|

|

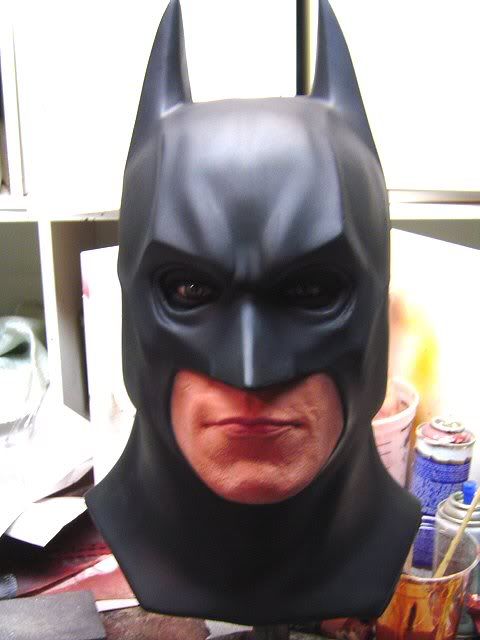

This was made from a one-piece mold.

Painting/eyes: Bob Causey

sculpture: Bob Dullam

|

|

|

|

Posted 9/25/2005 12:20:09 PM Posted 9/25/2005 12:20:09 PM |

|

|

Has NO LIFE!!

Last Login: 10/27/2014 6:30:59 PM

Posts: 4,811,

Visits: 18,798

|

|

I really don't like you guys.

I just can believe how amazing that is, as are all of your works. The best part is that you guys are will to take time out just to pass on a little of your vast knowledge to us. Thanks. P.S. ten years from now when you are tired of your Begins collect and decide to move on to what ever is hip at that time, PLEASE don't throw it away.

Bob, you have a PM.

|

|

|

|

Posted 9/25/2005 12:26:40 PM Posted 9/25/2005 12:26:40 PM |

|

|

You reap what you sow

Last Login: 9/19/2023 12:52:32 AM

Posts: 7,314,

Visits: 29,372

|

|

|

|

|

Posted 9/25/2005 1:04:03 PM Posted 9/25/2005 1:04:03 PM |

|

|

Forum Member

Last Login: 12/9/2018 8:47:32 AM

Posts: 432,

Visits: 2,210

|

|

| Jack, I just realized "I have a PM box here".. duh hilt.... anywho I will send you the "stuff". If you would share some of it with your friends here. not alot but, you might get some use out of it.

|

|

|

|

Posted 9/25/2005 1:11:17 PM Posted 9/25/2005 1:11:17 PM |

|

|

Has NO LIFE!!

Last Login: 10/27/2014 6:30:59 PM

Posts: 4,811,

Visits: 18,798

|

|

|

|

|