|

|

Posted 3/5/2010 8:50:32 PM Posted 3/5/2010 8:50:32 PM |

|

|

Getting Better at Internets

Last Login: 11/13/2022 6:06:37 AM

Posts: 2,698,

Visits: 8,392

|

|

Thats a good idea. i'm really not sure what i'm gonna do once all the "woodwork is done. Cleaning up the angles is a definate. Part of me really wants to study up and maybe cast molds and fiberglass myself a copy of the wood mock up. BUT, a second part of me feels like trying my luck at a vacuum forming machine and using these wooden mock ups as the part that will be cast in the plastic's machine. I'm not sure, its all just a toss up for now. But a definate is getting this wood mock up finished, and cleaned up, and identical, only in 1/2 scale. Its coming along so wonderfully and so easy! The two years of planning, and research are really paying off!

“It’s not who I am underneath, but what I do that defines me”

|

|

|

|

Posted 3/6/2010 8:02:42 PM Posted 3/6/2010 8:02:42 PM |

|

|

Getting Better at Internets

Last Login: 11/13/2022 6:06:37 AM

Posts: 2,698,

Visits: 8,392

|

|

Got a few more panels to share with you.

Lower Gas Panel:

Upper Gas Panel:

and the Box that sits underneath it all.

. .

All of these will make up the panel insert that was talked about earlier in this build.

This was all done today. Hope to get more done tomorrow.

“It’s not who I am underneath, but what I do that defines me”

|

|

|

|

Posted 3/7/2010 2:11:25 AM Posted 3/7/2010 2:11:25 AM |

|

|

You reap what you sow

Last Login: 9/19/2023 12:52:32 AM

Posts: 7,314,

Visits: 29,372

|

|

Really impressive. I just don't know how you manage your time to be able to accomplish all those plus other projects you have here at CLTC

|

|

|

|

Posted 3/7/2010 12:19:12 PM Posted 3/7/2010 12:19:12 PM |

|

|

Getting Better at Internets

Last Login: 11/13/2022 6:06:37 AM

Posts: 2,698,

Visits: 8,392

|

|

Well the 1/6 Keaton ended up flopping, i've been meaning to ask you if there was a way to just remove that build log.

The experimental side mechanics are still in the build/thought stage, and the batpod is on the back burner until i can get ahead on this project. Like Dave, i'm gonna stay focused.

I also believe that alot of my "success" is given towards the fact that i have a very involved family. My wife is VERY supportive to my bat-obsession, and she greatly shares my enthusiasm. My mother-in-law is fascinated with my ability, and actually had a huge hand in helping build Dave's Rumbler panels! My wife is tolerant to my lack of build space, and compromises so i can get my bat-builds done, and she can maintain her house.  Even my son, only 21 months old, greatly adds to my ability to build. He can tell the difference in my tools, and when i ask him to bring something to me, he knows what i need, and goes straight for it. If i ask him to stay off my papers (the prints for the templates) while i'm tacking them together, he will bend WAY out of his way to make sure that he goes no where near them. Even my son, only 21 months old, greatly adds to my ability to build. He can tell the difference in my tools, and when i ask him to bring something to me, he knows what i need, and goes straight for it. If i ask him to stay off my papers (the prints for the templates) while i'm tacking them together, he will bend WAY out of his way to make sure that he goes no where near them.

I often question how i have time to do all of this too. But, just like Daves saying about eating an elephant, or Grant, with his saying about take it slow, it all takes time, but hang in there and anyone can do it.

I have found that the more i work on the preparation side of things, the much-less time i put into the actual build. I bet if i put a little bit more time into it, i could make these templates where even a child of 5 could make this car. lol

Thanks for the kind words DH. And remember, these projects would not have been possible if it werent for you and the making of this site. YOU got this ball rolling. Thank you.

“It’s not who I am underneath, but what I do that defines me”

|

|

|

|

Posted 3/7/2010 3:56:03 PM Posted 3/7/2010 3:56:03 PM |

|

|

Getting Better at Internets

Last Login: 11/13/2022 6:06:37 AM

Posts: 2,698,

Visits: 8,392

|

|

i just saw the video saying that Grant sold his batmobile for a quarter of a million dollars.

....sure does make me wonder what i can get away with.  There isnt a Tumbler kit out yet. There isnt a Tumbler kit out yet.

“It’s not who I am underneath, but what I do that defines me”

|

|

|

|

Posted 3/7/2010 7:36:55 PM Posted 3/7/2010 7:36:55 PM |

|

|

Getting Better at Internets

Last Login: 11/13/2022 6:06:37 AM

Posts: 2,698,

Visits: 8,392

|

|

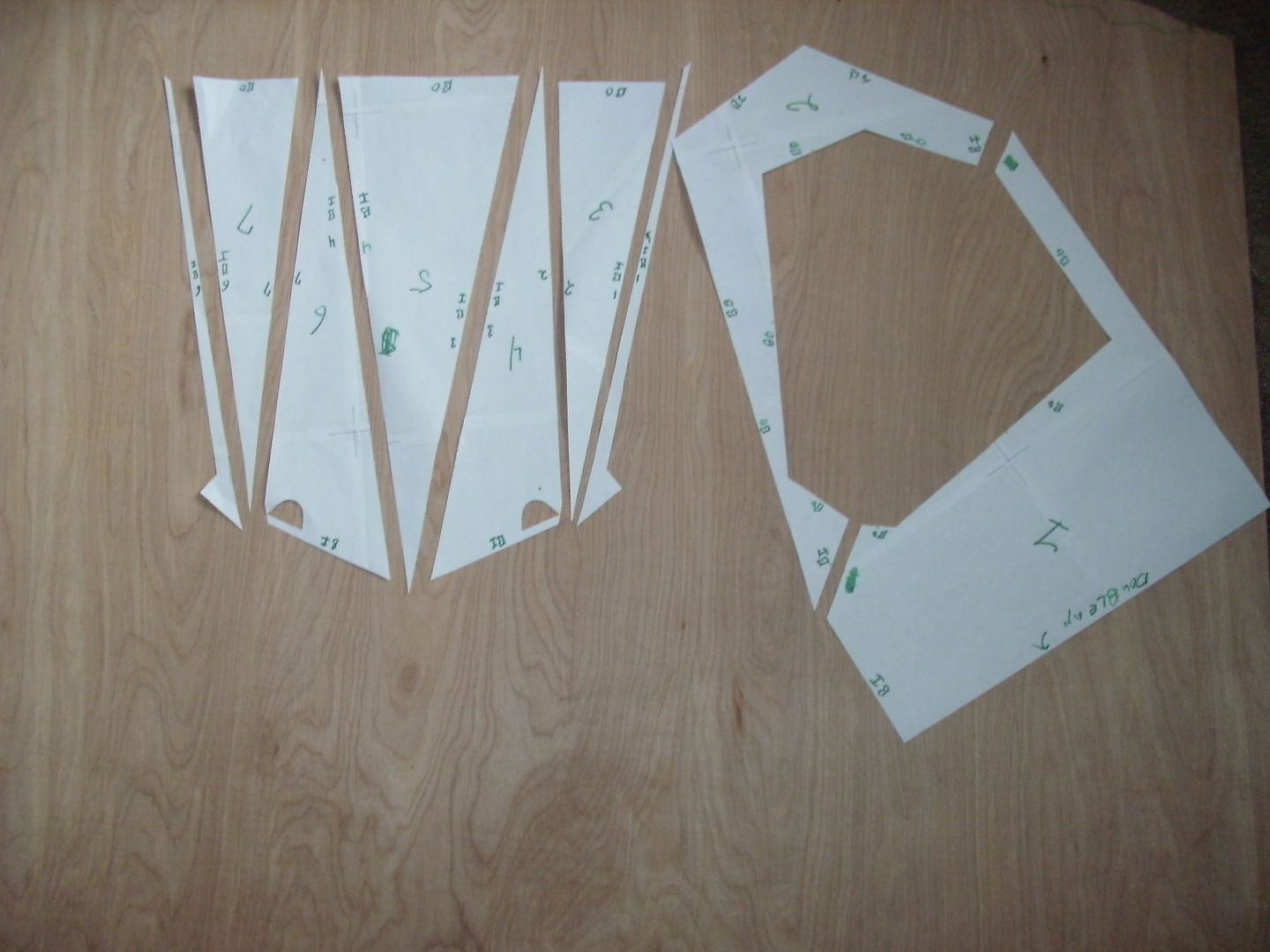

Thought i would share what goes into making a single panel.

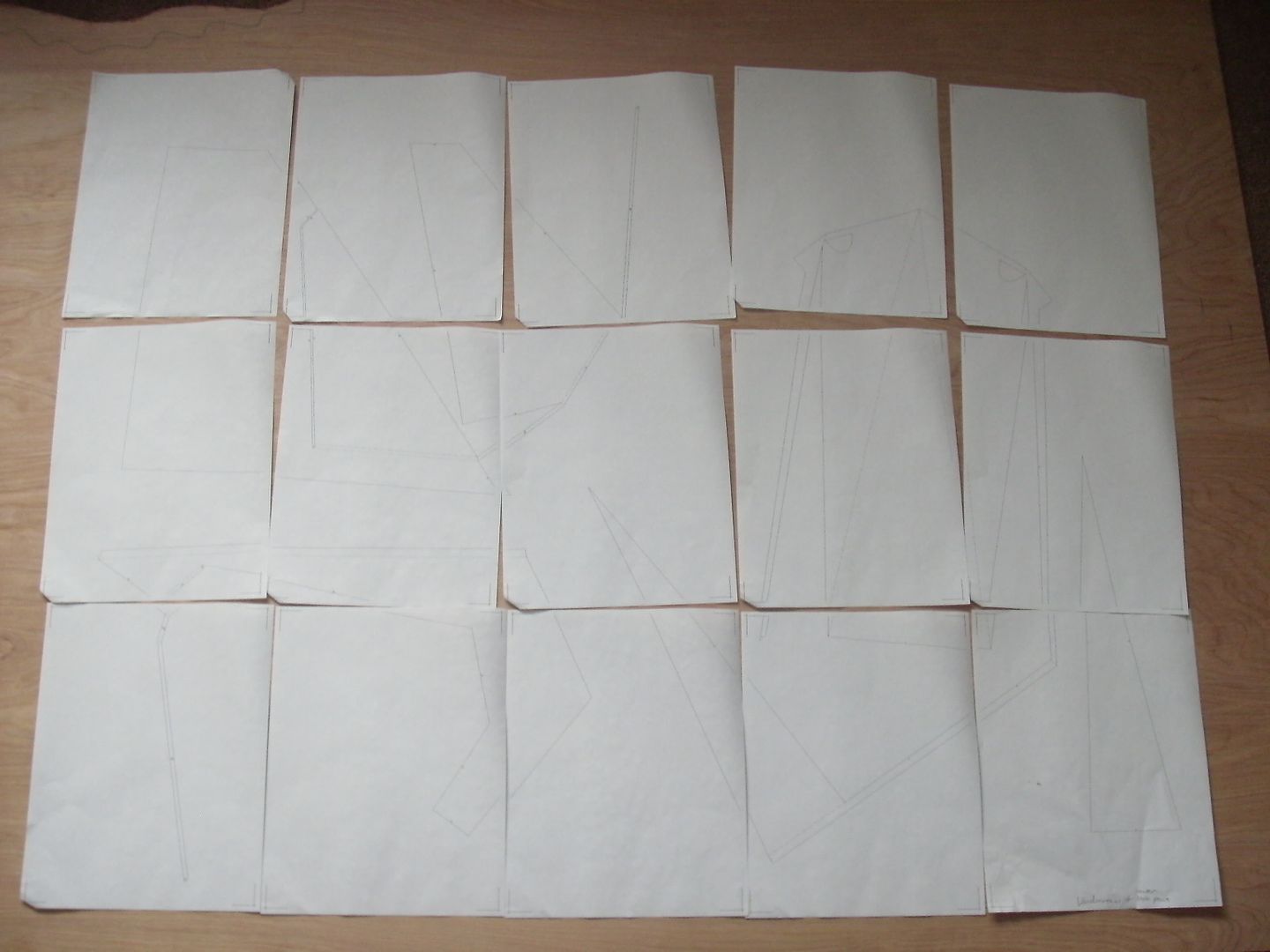

As shown before, the panel is created in 3d, exported to a program called pepakura, then from there, printed with line up marks. Here is the paperwork for the front windscreen, and center piece for the front two windows.

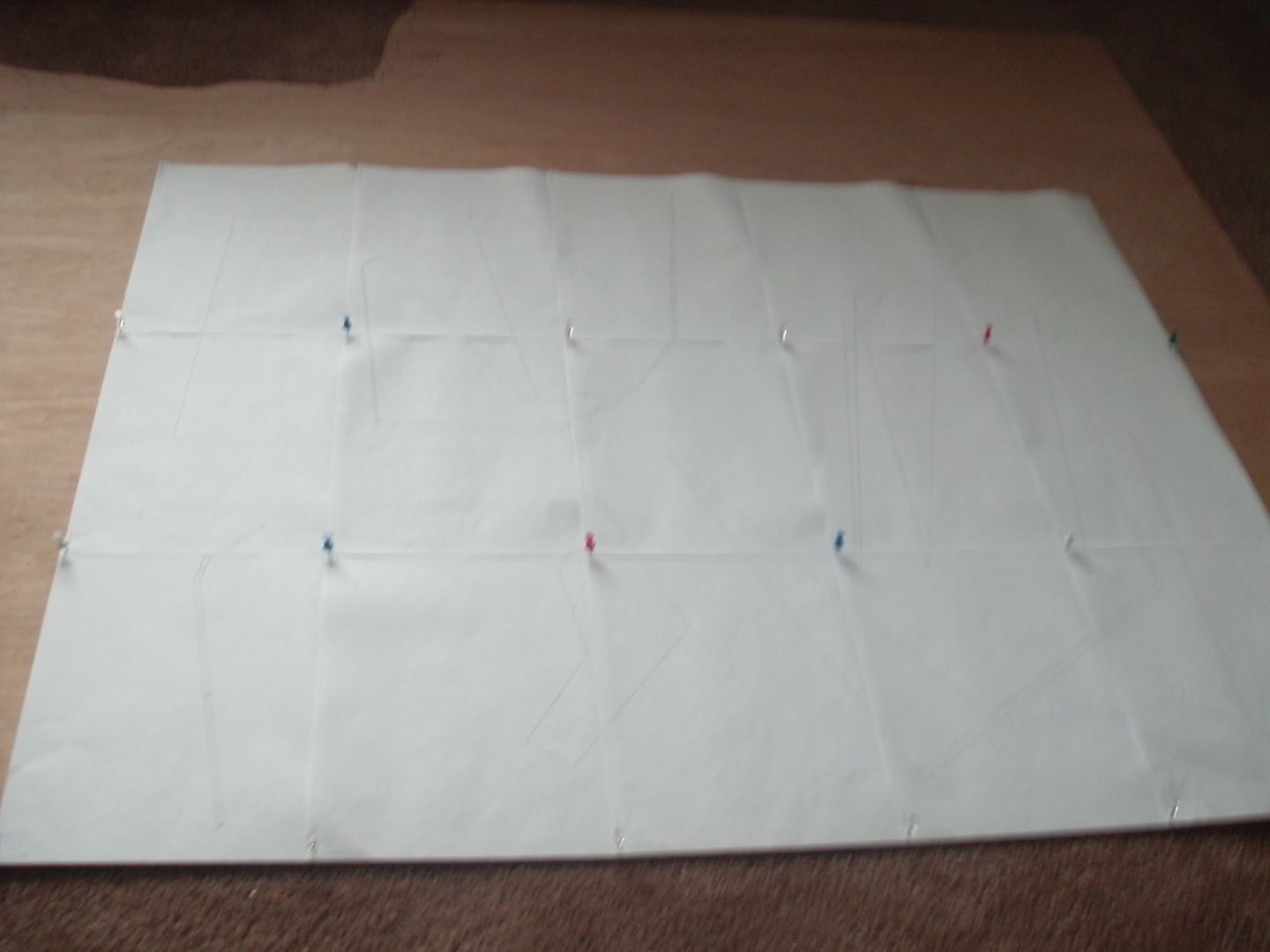

Then using the line up marks, the papers are aligned and tacked down. then taped in the appropriate areas.

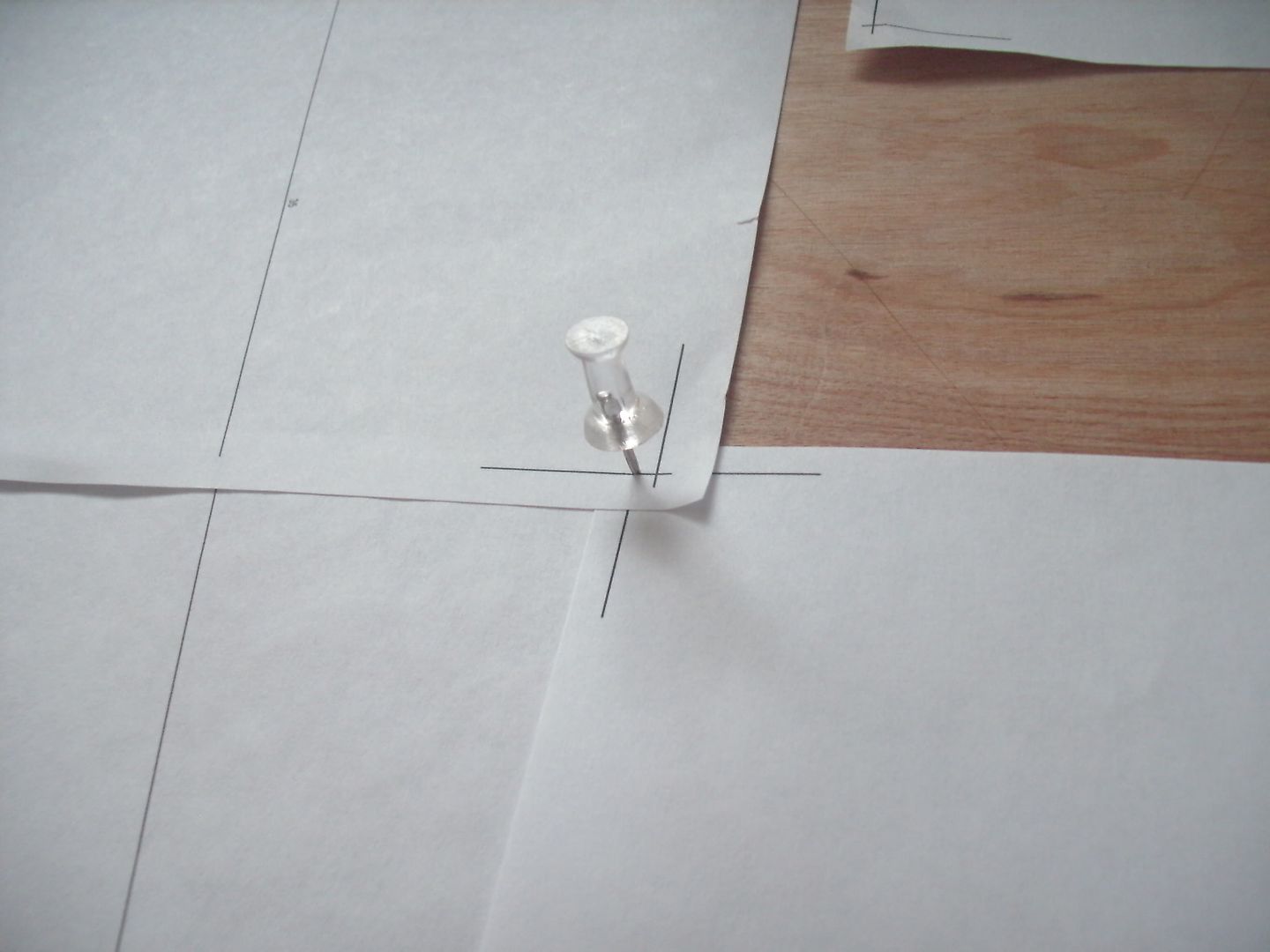

Sometimes you run into this, and its best to use your best judgement. Not everything is perfect. Even from 'puters.

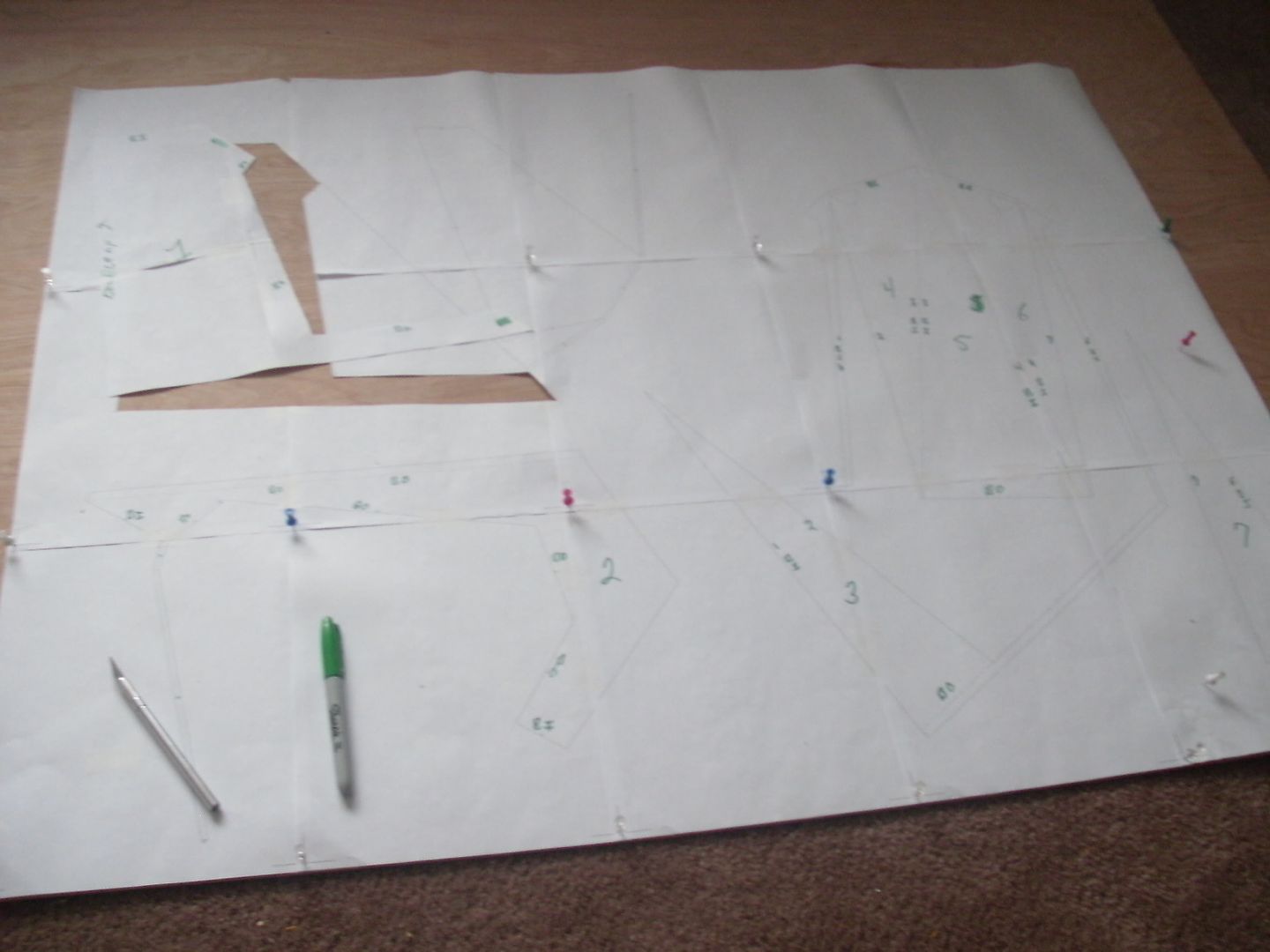

Then marked, with special information that i need to know on whether the part will be bent in at the corner, or out. Most of this information is off-the-top-of-my-head from here. After marked, its cut out.

From here the template is traced onto the plywoood, then cut out by the instructions i've written on them. This makes assembly fast and easy. I figure out the angle of which two pieces meet by using an angle finder. So making a panel is quick, but getting TO making the panel takes time.

“It’s not who I am underneath, but what I do that defines me”

|

|

|

|

Posted 3/8/2010 9:33:11 AM Posted 3/8/2010 9:33:11 AM |

|

|

Supreme Being

Last Login: 11/29/2023 6:02:47 AM

Posts: 1,214,

Visits: 3,970

|

|

Man.. that looks all too familiar

I did the exact same markings on all of the pieces and then I printed out a one page scaled version so that I could match it up like a puzzle.

---------------------------------------------------------

Building the BatBerry - Batmobile powered by BlackBerry

http://batberry.wordpress.com/

|

|

|

|

Posted 3/8/2010 2:58:25 PM Posted 3/8/2010 2:58:25 PM |

|

|

Forum Member

Last Login: 3/27/2018 12:29:27 AM

Posts: 499,

Visits: 2,545

|

|

Shaggy, very impressive!!  Noticed that the bends are cut out to put together. Would this be easier than bending metal? Noticed that the bends are cut out to put together. Would this be easier than bending metal?

|

|

|

|

Posted 3/8/2010 8:34:49 PM Posted 3/8/2010 8:34:49 PM |

|

|

Getting Better at Internets

Last Login: 11/13/2022 6:06:37 AM

Posts: 2,698,

Visits: 8,392

|

|

Honestly, i'm gonna say that of the two options, metal would have been a much better option.

Reason being is one: there is no wood grain to clean up OR cut edges to clean up.

and two:

Instead of having to take each panel and separating the individual faces, THEN reassembling, you can copy the template as one piece onto the metal, mark which direction it needs to be bent, and how much of a degree, and your done. I would have loved to go this route, but i dont have metal working machinery  . .

“It’s not who I am underneath, but what I do that defines me”

|

|

|

|

Posted 3/13/2010 1:29:38 PM Posted 3/13/2010 1:29:38 PM |

|

|

Getting Better at Internets

Last Login: 11/13/2022 6:06:37 AM

Posts: 2,698,

Visits: 8,392

|

|

Well i'm hoping to get started on the 1/2 Tumbler again today, but i got woke up at 5 this morning, my Father-n-law was needing the keys to my truck so he could go get his niece. His daughter, my sister-n-law, went into labor this morning and we are all just patiently waiting for news. So i have to be ready at the drop of a pin to go down to Port Orchard, and take everyone with me.

“It’s not who I am underneath, but what I do that defines me”

|

|

|

|